Control și asigurare a calității

NOVASTAR Committed to Quality at Every Step of Production

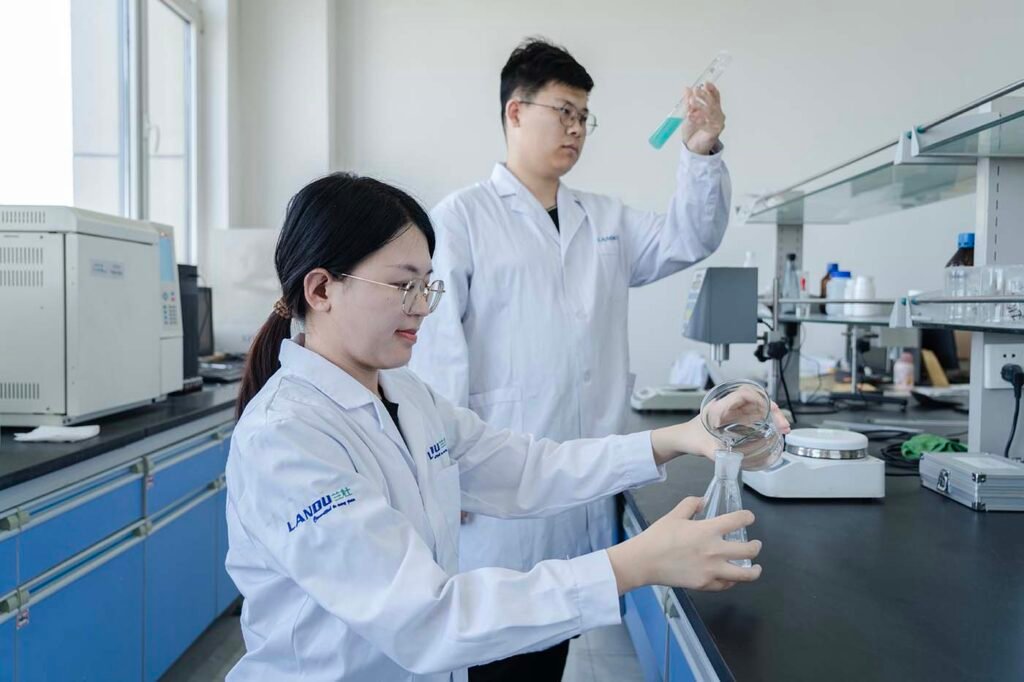

LANDU NOVASTAR is fully aware of the importance of quality in manufacturing. We define our quality control and assurance process from raw material selection to final sampling test and analysis. Not only do we identify and correct defects, but we are also committed to preventing them from occurring in the first place. This principle of LANDU NOVASTAR fosters and supports quality consciousness among factory employees, making everyone in LANDU pursue the best additives for our customers.

Eliminating Risk Before Production: NOVASTAR’s Raw Material Defenses

Supply Chain Management

Batch Tracking System

NOVASTAR only employs top-tier, fresh products through introducing a solid batch traceability process. This bulletproof batch tracking system helps us rapidly identify and find raw materials in storage, during shipment, or even in the hands of customers to avoid a potentially negative product recall.

Incoming Inspection

The Technology Behind NOVASTAR’s Flawless Additive Production

NOVASTAR’s Multi-Layer Consistency Safeguards

cURL Too many subrequests.

LANDU 15,000m² warehouse + An annual 75,000 tons capacity = Quality Consistency

Long-term Storage Testing

Simulate extreme conditions (-20℃ freezing to 50℃ high temperature) to ensure no crystallization or viscosity changes.

Compatibility Test Report

Compatibility reports with mainstream cement brands (such as Conch P·O 42.5 Lafarge CEMI)

Sampling inspection

Data-based test results for qualified additives before being released into the marketplace.

LANDU Certified Compliance for Responsible Production

Furthermore, with the principle of sustainable development certified by EcoVadis, LANDU NOVASTAR ensures sustainable production and takes responsibility for proper wastewater and gas discharge.